Fabric Grain & Cutting

Fabric grain influences stretch, stability, and alignment throughout the piecing process.

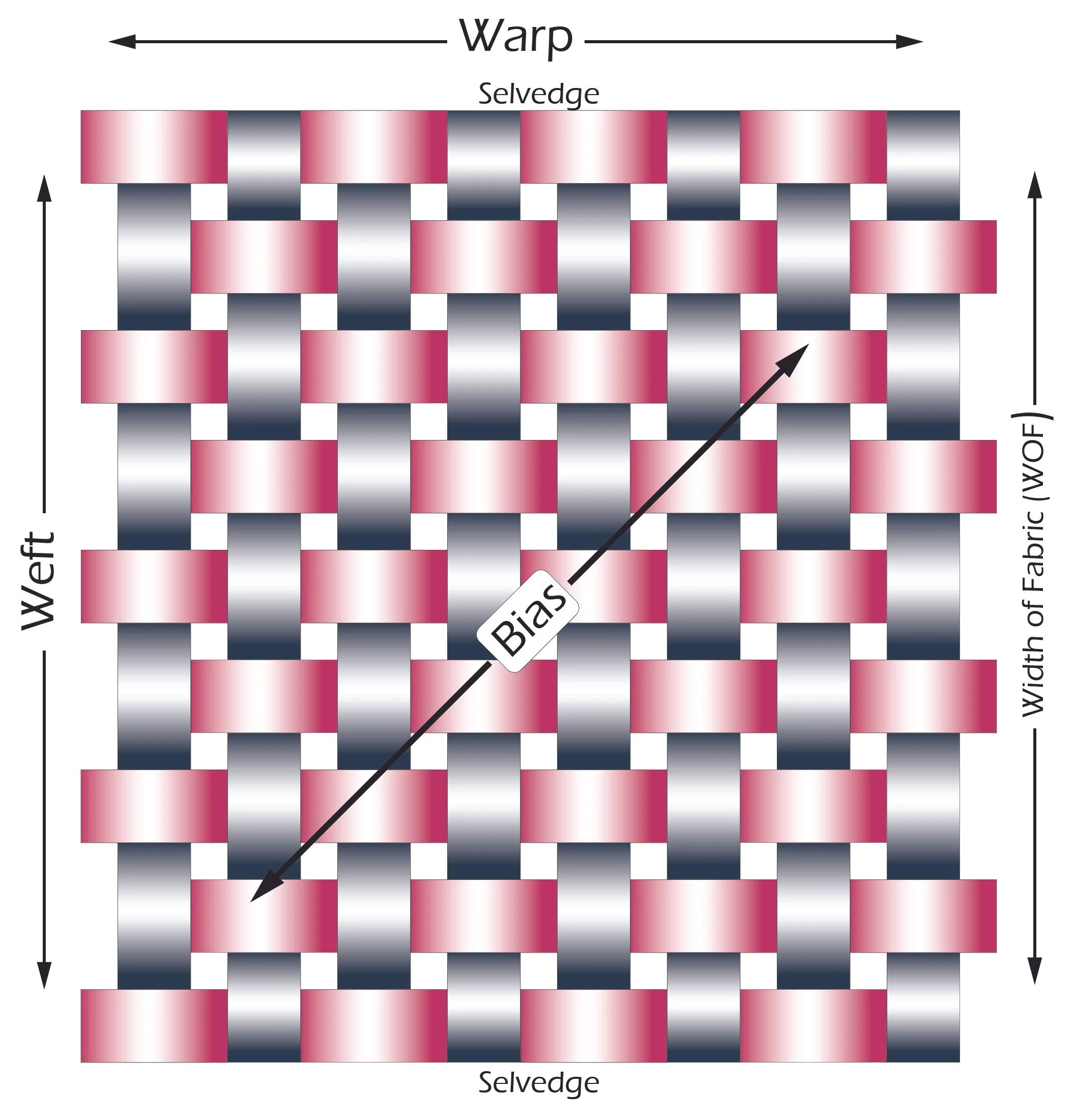

Here’s a quick reference to warp, weft, and bias, and why cutting direction matters in quilting.

Fabric Grain Directions

Selvedge

The finished edge of the fabric that runs parallel to the warp threads. It is tightly woven and does not stretch.

Width of Fabric (WOF)

The usable width of the fabric from selvedge to selvedge. For most commercial quilting cottons, this is about 42 inches, excluding the selvedges.

Warp (lengthwise grain)

Threads that run parallel to the selvedge. The warp is the most stable grain direction and has the least stretch.

Weft (crosswise grain)

Threads that run perpendicular to the selvedge. The weft is slightly less stable than the warp but still considered straight grain.

Bias

The diagonal direction at 45° to both warp and weft. The bias has the most stretch and flexibility.

Warp and weft together make up the straight grain of the fabric.

Pieces cut on straight grain are more stable and predictable, while bias-cut pieces stretch more easily and behave differently during piecing.

Cutting Considerations

Cutting along the straight grain (warp or weft) produces the most stable pieces and is preferred for most quilt construction.

Fabric cut on straight grain is less likely to stretch during sewing, which helps units finish at their intended sizes.

Pieces cut on the bias (45° to the grain) have more stretch and can distort, leading to uneven edges or blocks that finish larger or smaller than expected. That stretch can also affect how flat a quilt top lies once assembled, which in turn affects the quilting process. Excess distortion may result in rippling or folds that cannot be fully corrected through quilting.

When to Cut on the Bias

Bias cuts are useful when a design needs flexibility, such as curved seams or angled edges.

They can also help ease slight mismatches in length, but may distort if stretched during sewing.

When cutting on the bias, accurate cutting, careful handling, and controlled pressing are especially important.